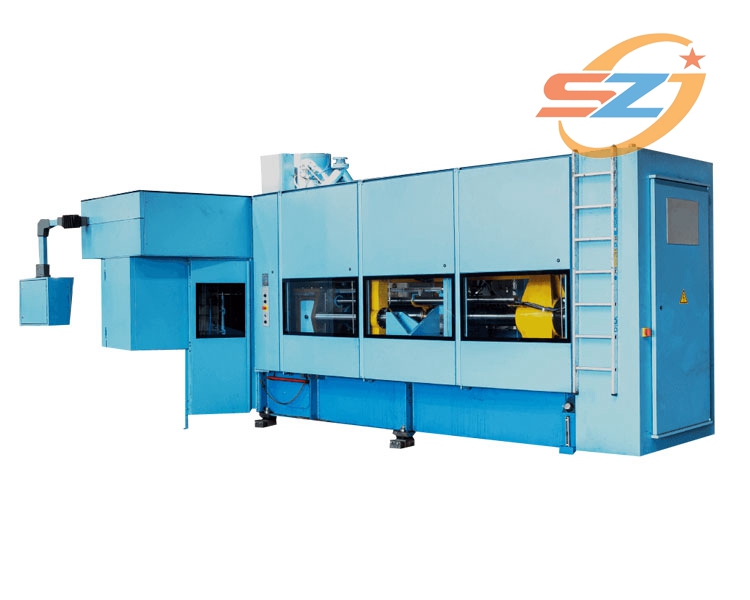

Vertical Parting Boxless Molding Machine

Vertical Parting Boxless Molding Machine

Vertical Parting Boxless Molding Machine is mainly used in automatic green sand casting workshop, which needs to be used in combination with green sand recycling processing equipment, because this equipment requires high quality of green sand, which needs to remove the iron bean splinter etc. in the old sand, and also needs to regenerate the old sand, 120-300 moulds/h, which is a special molding equipment for pedestrian cover, and the hardness of the mould sand is HB80-90 on average.Product Introduction

as molding machine) is suitable for mass production of small and medium-sized cast iron parts (gray cast iron, malleable cast iron, ductile iron), which has the characteristics of high production efficiency, high dimensional accuracy and surface quality of castings, low noise, low labor intensity, simple group line, less auxiliary machinery covers an area of small, low labor and construction investment, energy saving and good working environment.

characteristics of molding machine:

1. The electrical system adopts imported Mitsubishi programmable controller (PLC) for centralized automatic control of the main machine and auxiliary machines, PLC programming and adjustment is convenient, strong anti-interference ability, stable operation, well-designed program with perfect self-locking protection function and fault detection function.2. The process of conversion of each process is controlled centrally by PLC, and all kinds of parameters are adjusted through human-machine interface, and the whole molding process has dynamic display.

3. Hydraulic and pneumatic components are made up of standard components, and the whole machine has a high standardization level. The key hydraulic components and electrical components are imported, so that the whole machine has high reliability.

4. The mainframe cylinder adopts the combined cylinder structure, which simplifies the structure of the whole machine.

5. The hydraulic system is equipped with combined force control and pressure sensor, which ensures the synchronization of the main and auxiliary machines on the one hand and prevents the sand from being crushed, on the other hand, makes the utilization rate of the mould plate reach the maximum.

6. The bottom plate, side plate and top plate of the cavity are made of high hardness wear-resistant material with long life.

Composition of vertical molding machine:

It is composed of ten main parts: machine base, cavity (molding chamber), frame, positive platen mechanism, counter platen mechanism sand injection system, oil cylinder, hydraulic system, pneumatic system, electrical system and outer cover.

1. Machine base: the machine base is mainly composed of welded structural parts, it is the support of other parts of the machine, through the 14 foot screw holes of the machine base, the machine is fixed on the foundation, and the machine is adjusted to the horizontal position by adjusting the pads. There is a hole under the front part of the machine base and the back cavity of the positive pressure plate, which is used to accommodate the sand leaking out from the slit of the plate, and the sand can be cleaned out from the machine base by removing the cover plates on both sides of the front part of the machine base.

2. Cavity frame: It is mainly composed of upper and lower frame, side frame, top plate, side plate, bottom plate, guide pillar, back frame (supporting cylinder) cross bracket and other assemblies. The top plate, bottom plate and side plate of the working surface of the cavity are connected to the frame with screws. This can easily replace the cavity working surface without disassembling the frame of the molding chamber.

3. Positive pressure plate mechanism: it is mainly composed of plate body, heater, vibrator, stroke position slide tube, etc. The positive pressure plate is connected with the piston of the front cylinder, and it moves with the piston to perform the action of compaction, pushing and closing, starting mold 2 and other processes, and signals the position of the positive pressure plate through the position sensor. It is also equipped with sliding pads that can be adjusted in height to facilitate adjustment and ensure that the piston is concentric with the cylinder during movement.

4. Counter-pressure plate mechanism: It is mainly composed of plate body, heating liner, heater, vibrator, sand blowing clean nozzle, counter-pressure plate frame, four-link mechanism and so on. It is connected to the counter-pressure plate cylinder piston through four guide pillars and cross brackets, and moves with the piston to execute the action of starting the mold 1 and closing the cavity in two processes. The position signal of the counterpressure plate is sent through the position sensor on the guide pillar, and the counterpressure plate body is adjusted in the horizontal direction in order to adjust the accuracy of the whole machine, and the four adjusting pillars on the frame of the counterpressure plate are used to adjust to ensure that the counterpressure plate is in vertical position with the bottom plate when shooting sand and starting the mold.

5. Sand injection system: It is mainly composed of gas storage tank, sand injection cylinder, sand gate mechanism, sand injection valve, quick discharge valve, material level meter, etc. The sand injection pressure of the gas tank is controlled by two pressure reducing valves, and the general pressure is adjusted at 0.3MP-0.4MP. The opening time of the sand injection valve can be adjusted by electrical control, and the amount of sand contained in the sand injection cylinder is generally 1.5 times of a sand type, and after the amount of sand is full, there is a level meter to signal the sand adding machine to stop adding sand and close the sand gate.

6. Oil cylinder: the front cylinder (driving the positive platen movement) and the rear cylinder (driving the reverse platen movement) are arranged along the coaxial line, the cylinder adopts the form of combined cylinder, except for the compaction process, in the rest of the cylinder action process, the pressure oil of the working oil circuit only enters the small area oil cavity to achieve the rapid movement of the piston.

7. Hydraulic system principle description

The hydraulic system components are basically standard parts. The oil circuit is divided into two parts: the control oil circuit and the working oil circuit. The control oil circuit is provided by the duplex vane pump, and the first level pressure oil controls the swing angle of the oil pump itself, so that the cylinder piston can realize the expected variable speed movement to meet the requirements of the machine working process. Compaction pressure adjustment value is the user required compaction pressure value (recommended to use 7-9MP) combined type force value is adjusted to 4-5MP, pressure sensor controls the machine''''''''''''''''''''''''''''''''s compaction ratio pressure size, adjust the pressure value higher, will improve the compaction ratio pressure, note that once the pressure sensor pressure value is changed, the three-stage overflow should also be adjusted accordingly. The tubular heater, cooler and oil temperature measuring sensor and its control oil circuit constitute the oil temperature control link to make the oil temperature stable at 35-45 degrees to ensure the stable operation of the hydraulic system.

8. Electrical system principle description

The system adopts AC 380V power supply (three-phase five-wire system is required), the control circuit adopts AC 220V power supply, the whole machine has manual, single-action, full-line linkage, and manual down core function, with start, stop, stop, emergency stop button. The process flow of the main machine is cavity closing - sand shooting - compaction - mold starting 1 - pushing out the mold closing - mold starting 2. When there is an emergency need to stop, it can stop in the middle, emergency stop. The emergency stop is to disconnect the power supply of the control part, the middle stop is to disconnect the output of the solenoid valve, when the next time in the start from the location of the stop, when the stop button is pressed, the whole line to go through a cycle in the initial position to stop.